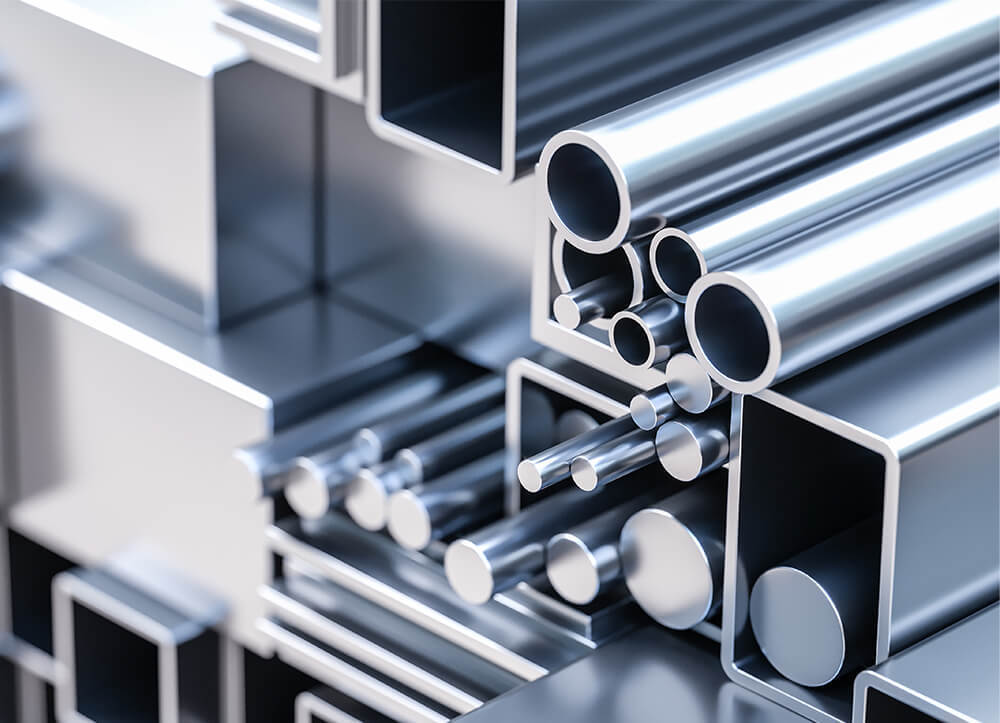

ALUMINIUM PRODUCTS

Home > Products

PRODUCTS

Contact Info

Support for Your Business

Info File

Copper Forgings Specification

| Standard | ASTM B124, ASME SB124 |

| Specification | DIN, ASTM, BS and all International Standards |

| Flat bar blocks | up to 27″ width and 15,000 lbs. |

| Cylinders and sleeves | up to 50″ maximum O.D. and 65″ maximum length |

| Discs and hubs | up to 50″ diameter and 20,000 lbs. |

| Rolled, hand forged or mandrel forged rings | up to 84″ maximum O.D. and 40″ maximum length |

| Rounds, shafts and step shafts | up to 144″ maximum length and 20,000 lbs. |

| Forging Types | Impression Die Forging, Open Die Forging, Seamless Rolled Forging, Hot Forging, Cold Forging, Open die hammer forging, Impression die drop forging, Closed Die Forging, Press Forging, Upset Forging, Compression Forging, Swaging, Rotary Forging, Roll forging. |

Vimal Metals is a prominent manufacturer specializing in aluminium alloy bars, rods, and plates. Their offerings are likely designed to meet the diverse needs of various industries, such as aerospace, automotive, construction, marine, and consumer goods. Here’s an overview of the types of products Vimal Metals might offer and their potential applications:

Aluminium Alloy Bars Characteristics: High Strength: Suitable for structural applications.

Corrosion Resistance: Ideal for use in harsh environments.

Workability: Easy to machine and form.

Applications: Automotive Components: Axles, engine blocks, and frames.

Construction: Structural frameworks, supports, and reinforcements.

Aerospace: Aircraft components requiring high strength and low weight.

Aluminium Alloy Rods Characteristics:

Durability: Withstands high stress and pressure.

Versatility: Available in various sizes and tempers.

Conductivity: Good electrical and thermal conductivity.

Applications Machinery: Shafts, pins, and gears.

Electrical: Conductive rods for electrical applications.

Marine: Boat fittings and structural parts.

Aluminium Alloy Plates Characteristics:

Flatness and Precision: Manufactured to tight tolerances.

Heat Treatability: Can be hardened or softened as needed.

Surface Quality: Smooth and suitable for high-finish applications.

Applications:

Aerospace: Fuselage panels, wing skins, and bulkheads.

Tooling: Molds, jigs, and fixtures.

Construction: Facades, roofing, and flooring.

Benefits of Choosing Vimal Metals

Quality Assurance: Adherence to international standards and rigorous quality control.

Customization: Ability to produce alloys tailored to specific customer requirements.

Expertise: Experienced in handling complex alloy compositions and manufacturing processes.

Sustainability: Commitment to eco-friendly practices, including recycling.

Vimal Metals, as a leading manufacturer of Aluminium Alloy Bars, Rods, and Plates, plays a crucial role in providing high-quality materials that cater to the needs of various demanding industries. Their products’ versatility, strength, and reliability make them a preferred choice for manufacturers seeking top-notch aluminium alloy solutions.

- ALUMINIUM